What is an industrial vacuum used for?

Regular vacuums can't handle cement dust, metal shavings, or oil spills—but that's where industrial vacuums come in.

Industrial vacuum cleaners1 are used for heavy-duty cleaning tasks2 in factories, warehouses, and job sites like construction and demolition, where fine dust and hazardous debris3 are common.

industrial vacuum use case

A customer from Australia, Polivac, once told me: “This is for concrete and sanding dust collection.” That single sentence sums up the industrial challenge. Industrial vacuums are not one-size-fits-all. They’re purpose-built machines that depend on the user’s specific environment—be it a construction site, a metal workshop, or a chemical facility. Let’s break down what really makes these machines different.

What is the industrial application of vacuum?

Factories, workshops, and job sites all have one thing in common—dust and debris that regular vacuums can’t handle.

Industrial vacuums are applied in sectors like construction, manufacturing, food processing, and chemical handling to control dust, remove hazardous material4, and ensure operational safety5.

industrial vacuum application

Industry-specific applications

Industrial vacuums are built for reliability and power. They clean where manual tools and regular vacuums fail. In construction, they remove silica dust from concrete. In woodworking, they collect sawdust directly from machines. In pharmaceuticals, they maintain cleanrooms. Each environment sets different safety and performance requirements.

| Industry | Cleaning Target | Why Industrial Vacuum? |

|---|---|---|

| Construction | Concrete/sanding dust | Complies with OSHA silica dust rules |

| Manufacturing | Metal shavings, oil mist | Handles high volume, high density waste |

| Food Processing | Powder, crumbs, spills | Food-grade filters, stainless steel design |

| Chemical Plants | Toxic/fine particles | Explosion-proof models available |

| Warehouses | Pallet debris, packaging dust | Durable filters and large capacity tanks |

The real power of industrial vacuums lies in their adaptability.

What is the difference between a regular vacuum and an industrial vacuum?

They may look similar at first glance—but internally, the difference is night and day.

Industrial vacuums are stronger, more durable, and more customizable than regular vacuums, designed to work longer and survive harsh environments.

industrial vs regular vacuum

Built to last, not for living rooms

A regular vacuum can handle carpets and household dirt. But bring it to a demolition site, and it’ll break in minutes. Industrial vacuums are made for long working hours, large debris, corrosive materials, and explosive dust. They have advanced filters, more powerful motors, and large collection tanks.

| Feature | Regular Vacuum | Industrial Vacuum |

|---|---|---|

| Motor Power | < 1.5 kW | 1.5–7.5 kW or more |

| Filter System | Basic foam or HEPA | Multi-stage HEPA + cyclone or cartridge |

| Durability | Domestic plastics | Steel, aluminum, or impact-proof polymer |

| Use Time | Short sessions | Continuous use (8+ hours) |

| Application | Household | Industrial floors, factories, hazardous dust |

So if your vacuum breaks down after an hour at the site—it was never meant to be there.

What is the range of vacuum in typical industrial applications?

Not all vacuums are created equal—some are made to move powder, others to suck up bolts.

Vacuum strength for industrial use varies from 1000 mmH₂O6 for general debris to over 3000 mmH₂O7 for heavy particulate and liquids.

vacuum pressure range

Matching vacuum pressure to the job

In the vacuum world, suction power8 is measured in mmH₂O or kPa. More pressure means better performance with heavy or dense debris. Construction jobs may need mid-range suction to pull in fine cement dust. Metal factories might demand higher suction to collect shavings or oily waste.

| Job Site Type | Recommended Vacuum Pressure (mmH₂O) |

|---|---|

| Light dust collection | 1000–1500 mmH₂O |

| Cement/concrete cleanup | 1800–2500 mmH₂O |

| Liquid + solid debris | 2000–3000 mmH₂O |

| Toxic/HEPA applications | 2200+ with sealed systems |

Choosing the wrong vacuum pressure isn’t just inefficient—it can damage the vacuum or leave behind harmful dust.

Which vacuum cleaner is best for industrial use?

No one vacuum fits all needs—but some models outperform the rest in reliability, filtration, and power.

The best industrial vacuum is one tailored to your task—with strong suction, multi-stage filtration, and a durable build for your working conditions.

best industrial vacuum

My approach to recommending vacuums

I always ask clients three questions: What are you cleaning? For how many hours per day? Indoor or outdoor use? For instance, Polivac needed a vacuum for concrete sanding dust. That called for a cyclone pre-separator, HEPA filter, and high negative pressure—around 2500 mmH₂O. We built them a model that ran 10 hours per day without overheating or clogging.

| Key Feature | Why It Matters |

|---|---|

| HEPA Filter | Protects lungs from fine particles |

| Cyclone Separation | Extends filter life |

| Metal Frame | Withstands job site abuse |

| Continuous Motor | Runs for 8+ hours per shift |

| Wet & Dry Compatibility | Handles all cleaning types |

Best is not the biggest. Best is what works best for your job.

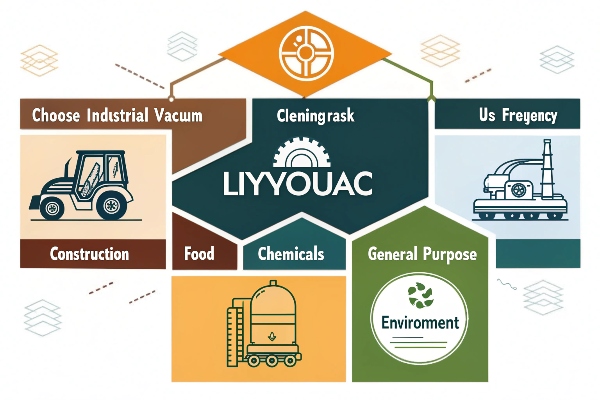

How do I choose an industrial vacuum cleaner?

Choosing blindly often leads to regret. Choose based on the job, not just the price tag.

You should choose an industrial vacuum based on what you’re cleaning, how often, and what environment it will be used in—construction, food, chemicals, or general use.

how to choose industrial vacuum

My 5-step checklist

Here’s the process I walk my buyers through:

- Debris Type – Is it fine powder, oily waste, or explosive dust?

- Filtration Needs – Do you need HEPA or antistatic filters?

- Usage Time – Will it run all day or a few hours a week?

- Mobility – Do you need wheels or forklift handling?

- Compliance – Do you need CE, ISO, ATEX certifications?

| Criteria | Questions to Ask |

|---|---|

| Dust Type | Is it fine, sticky, or combustible? |

| Filter Requirement | Is HEPA or antistatic filtering required? |

| Run Time | Daily hours of use? |

| Power Source | Single-phase or three-phase? |

| Disposal Method | Manual or auto-dust discharge? |

I often remind my clients: the right vacuum doesn’t cost—it pays back in durability, safety, and time saved.

Conclusion

Industrial vacuums are not just larger—they're smarter, stronger, and tailored for serious work. Choosing the right one means cleaner operations and safer teams.

-

Explore this link to understand how Industrial vacuum cleaners enhance safety and efficiency in heavy-duty cleaning tasks. ↩

-

This resource will provide insights into various heavy-duty cleaning tasks and the equipment best suited for them. ↩

-

Learn about best practices for managing hazardous debris to ensure safety and compliance in industrial environments. ↩

-

Learn about the critical role of industrial vacuums in safely managing hazardous materials. ↩

-

Discover best practices that enhance operational safety in workplaces using industrial vacuums. ↩

-

Learn about the significance of 1000 mmH₂O in vacuum strength to ensure effective cleaning and debris management in industrial settings. ↩

-

Discover why 3000 mmH₂O is essential for handling heavy materials, ensuring optimal performance in industrial vacuum systems. ↩

-

Understanding suction power is crucial for selecting the right vacuum for specific tasks. Explore this link to learn more about its measurement and significance. ↩