How Are Vacuums Manufactured? The Intricate Process Behind Your Household Essential

Curious about how your trusty vacuum comes together? The manufacturing process is a fascinating journey from raw materials to a polished product.

Vacuums are made through a series of stages: injection molding for plastic parts, assembly of components, quality control[^1], and packaging. Each step is essential to ensure reliability and top-notch performance, making vacuums indispensable household devices.

From shaping plastic with heated thermoplastic sheets to rigorous quality tests under the 5S methodology, the process is a showcase of precision and technology.

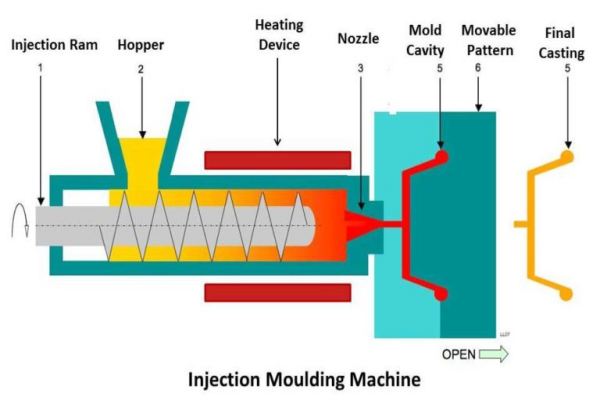

Injection Molding: The Backbone of Vacuum Construction

Wondering how vacuums take shape? Injection molding is a critical part of the process.

Injection molding uses heated thermoplastic sheets molded under pressure to form plastic parts like the vacuum casing and hose. This technique ensures durability and precise shape, establishing a sturdy foundation for the vacuum's construction.

With automation and CNC machining, manufacturers achieve consistent results, essential for high-quality production.

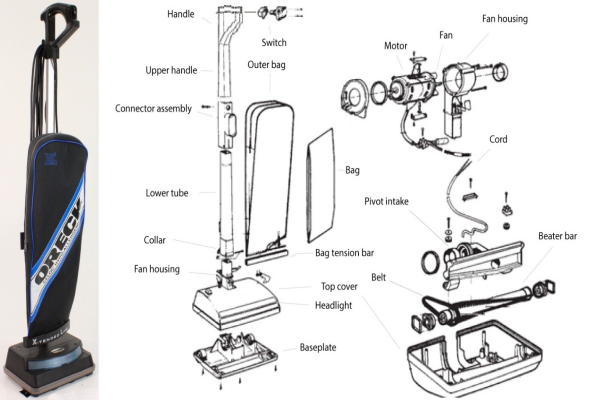

The Step-by-Step Assembly of Vacuum Components

Ever considered how vacuums are pieced together? It's a collaborative effort of machines and skilled hands.

The assembly of vacuums[^3] involves attaching components like the motor, fan, filters, and electronics. Done on automated or manual lines, this process requires precision and coordination to ensure the vacuum operates smoothly and efficiently.

With each piece meticulously aligned and secured, the vacuum comes to life, ready to fulfill its duty.

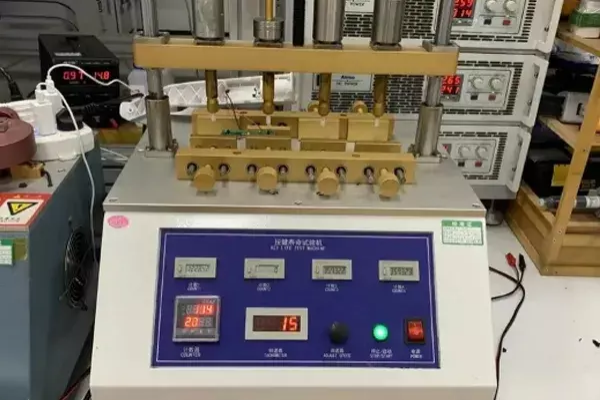

Quality Control in Vacuum Manufacturing: Ensuring Excellence

How do manufacturers ensure vacuums never miss a beat? Rigorous quality control is the answer.

Quality control in vacuum manufacturing is comprehensive, assessing motor performance, battery safety, suction power, and aesthetics. Under the 5S methodology, each unit undergoes thorough testing, guaranteeing it meets the highest standards before reaching consumers.

This meticulous attention to detail guarantees efficiency and reliability, key to consumer satisfaction.

The Role of Automation and Skilled Workers in Vacuum Production

Curious about the balance between technology and craftsmanship in manufacturing? The fusion is seamless.

Modern vacuum production involves a blend of automation and skilled labor. Automation, aided by CNC machining[^4], ensures high production volumes, while skilled workers handle intricate assembly tasks, balancing efficiency with human oversight.

This synergy of human skill and cutting-edge technology produces products that are both high-quality and high-volume.

Efficient Packaging: The Final Step in Vacuum Manufacturing

What protects vacuums on their journey from factory to home? Well-thought-out packaging.

Vacuum packaging[^5] is designed to safeguard during transit, often utilizing automated packing solutions. By coordinating elements like material strength and form-fit packaging, the process ensures that each vacuum arrives in perfect condition.

Through effective planning and execution, packaging is the final touch in delivering a pristine product to the consumer’s doorstep.

[^1]: Learn about quality control practices that ensure product reliability and performance in manufacturing. [^2]: Explore this link to understand the injection molding process, crucial for creating durable vacuum parts. [^3]: Discover the intricate processes involved in vacuum assembly, highlighting the blend of technology and craftsmanship. [^4]: Explore this link to understand how CNC machining revolutionizes production efficiency and precision in manufacturing. [^5]: Discover the advantages of vacuum packaging to ensure your products arrive safely and in top condition.