Are industrial vacuums flooding your options list? Choosing the right one can save you hours of hassle and money. Let me guide you through the essential aspects for the perfect machine fit.

Select by assessing key features like dust container capacity, working duration, product quality, and dust filtration performance to suit your specific industrial needs.

Industrial vacuum cleaners are indispensable in many settings, from production facilities to commercial spaces. Choosing the right one isn't just about efficiency—it's integral to maintaining operational productivity and minimizing downtime. I've gathered the following insights through years of experience and expertise in the vacuum industry.

How many watts is an industrial vacuum cleaner?

Confused about energy specs? Wondering about wattage versus efficiency1? Learn how watt choice impacts your vacuum’s performance.

Industrial vacuum cleaners range between 1000 to 3000 watts2—selecting the right wattage balances performance needs with energy costs.

Understanding wattage is crucial for informed vacuum choice. Typically ranging from 1000 to 3000 watts, the correct wattage ensures efficiency in demanding applications.

Considerations:

- Task Complexity: Simple debris needs may require lower wattage, while heavy-duty tasks demand higher power.

- Energy Conservation: Models that integrate energy-saving technology can balance performance with cost and sustainability.

- Space Size: A larger space often implies a need for higher wattage, ensuring thorough and swift cleaning.

Discussing these specifications with clients like Kevin Huang, who seeks optimal performance within budget constraints, is crucial in pinpointing the best fit for industrial applications.

Are industrial vacuums3 worth it?

Concerned about the cost of industrial vacuums? Wondering if the investment pays off? Find out why these machines offer unmatched value in certain environments.

Indeed, for industries needing robust cleaning solutions, industrial vacuums offer durability4, efficiency5, and capability beyond standard models.

Why invest in industrial vacuums? They are unquestionably worthwhile for businesses facing heavy debris and ongoing cleanups. Unlike home vacuum cleaners, industrial models deliver longevity and performance across various environments.

Evaluating Value:

- Extended Durability: Built for tough environments, they reduce replacement and maintenance expenses.

- Superior Efficiency: Enhanced airflow and suction power ensure quick cleaning while boosting productivity.

- Cross-Industry Utility: They adapt to specific demands from metal fabrication, food processing, pharmaceuticals, and chemicals.

Working with distributors like Kevin, it's clear industrial vacuums provide a competitive edge, vital in changing markets.

How do I choose an industrial vacuum cleaner?

Overwhelmed by vacuum options? Fearing a poor choice? Understand the steps for selecting a machine aligned with your requirements.

Define the cleaning scope and assess motor design, build quality, suction level6, filtration systems7, and after-sales support for a comprehensively matched industrial vacuum cleaner.

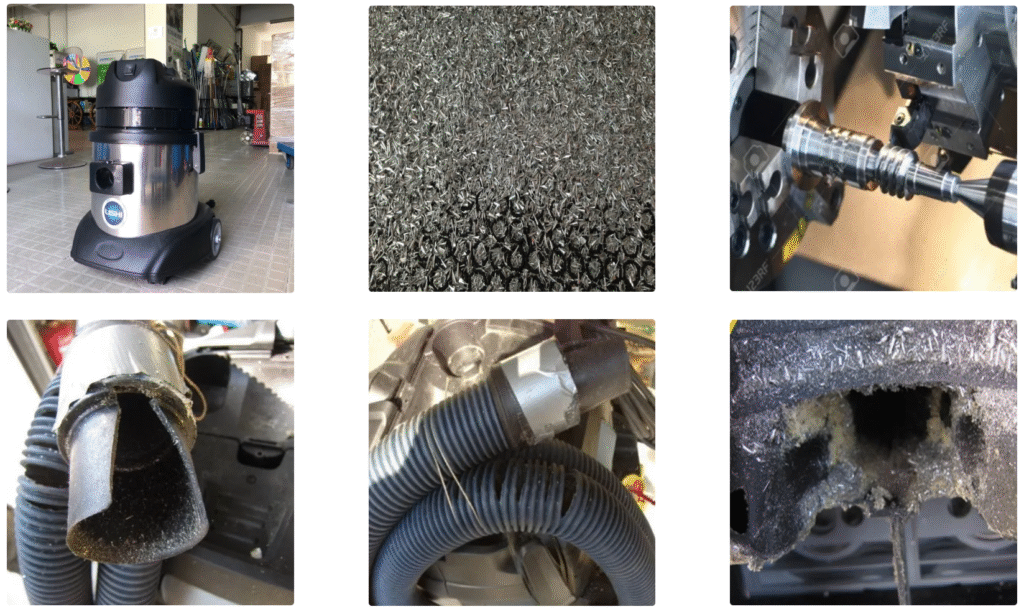

Person comparing various industrial vacuum models

Choosing an industrial vacuum involves careful analysis of specs in relation to your specific cleaning needs. Here’s how I guide my clients.

Selection Guidelines:

- Identify Cleaning Needs: Are you dealing with dust, debris, or liquid spills? Each application demands different features.

- Motor Evaluation: Opt for versatile motors, capable of wet and dry tasks with adequate protection.

- Suction Power Analysis: The right CFM (airflow) and Water Lift (sealed suction) are crucial for effective cleanup.

- Construction Quality: High-durability materials ensure long-term operational reliability.

Technical Specs Overview:

| Feature | Home Vacuum | Industrial Vacuum |

|---|---|---|

| Size | Compact | Large, heavy-duty |

| Power (W) | 500-1000 | 1000-3000 |

| Voltage | 110-240V | 380-480V (Three-phase) |

| Filtration System | Basic/HEPA | Advanced Multi-stage |

| Application | Indoor | Factories, Workshops |

These selections guarantee suitability for operational demands and budget adherence.

What is the industrial vacuum level?

Uncertain about "vacuum levels"? Afraid of mismatched specs? Discover how this term defines suction power for industrial vacuums.

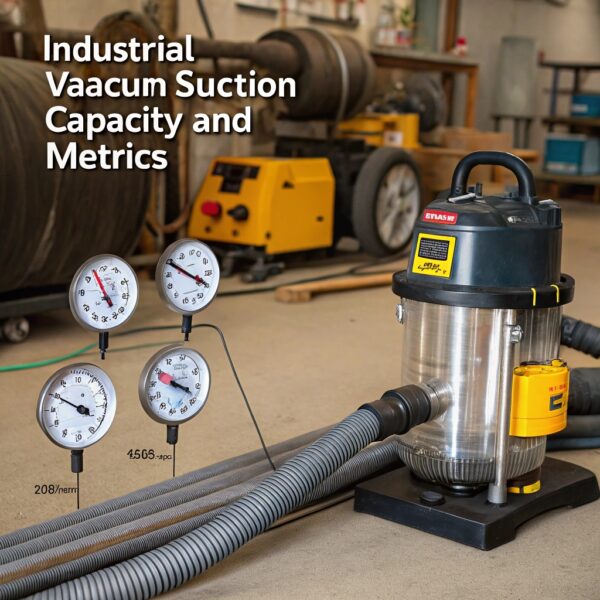

Industrial vacuum levels reflect suction capacity, measured in CFM or Water Lift. High levels of 150+ CFM and 80+ inches Water Lift are ideal for industry applications.

Graph illustrating industrial vacuum suction levels

"Vacuum levels" refer to the machine's ability to move air, picking up dirt efficiently. In industrial settings, this translates to potent suction necessary for challenging tasks.

Industry Specifications:

- CFM (Airflow): Indicates the volume of air moved, with 150+ CFM being optimal for heavy-duty cleaning.

- Water Lift (Suction Force): Represents suction intensity, where industrial models should have 80+ inches.

These measurements help distinguish industrial vacuums from more general-use models, ensuring effective cleaning.

What is the best vacuum cleaner with the most suction?

Searching for the best high-suction vacuum? Fearful of weak performance? Discover the features that define superior cleaning ability.

Aim for models balancing peak horsepower with efficient CFM and Water Lift figures. These provide exceptional cleaning performance in diverse environments.

Image displaying high-suction industrial vacuum cleaners

For superior suction, balance horsepower, airflow (CFM), and suction (Water Lift). This ensures maximum cleaning capability across varied scenarios.

Selection Criteria:

- Balanced Power: Focus on strong CFM and Water Lift rather than just high horsepower.

- Advanced Features: Look for additional functions such as blower capabilities or smart control systems.

A well-chosen vacuum leads to excellent performance suited for industrial demands and niche applications.

Conclusion

Select your industrial vacuum by considering container size, operational hours, build quality, and filter efficacy. These are the cornerstones for reliable, high-performance cleaning.

-

Exploring this relationship can help you optimize your cleaning tasks while managing energy consumption effectively. ↩

-

This range is crucial for balancing performance and energy efficiency, making it essential for informed purchasing decisions. ↩

-

Explore the advantages of industrial vacuums to understand their value in various industries and how they can enhance cleaning efficiency. ↩

-

Learn about the significance of durability in industrial cleaning equipment and how it impacts long-term investment and performance. ↩

-

Discover how industrial vacuums enhance cleaning efficiency, making them a worthwhile investment for businesses with demanding cleaning needs. ↩

-

Discover why suction level is crucial for effective cleaning and how it influences your choice of vacuum cleaner. ↩

-

Learn about various filtration systems and their impact on vacuum performance, helping you make an informed decision. ↩